What is Nitrogen & what is It Used For?

Nitrogen gas is a colorless, odorless, and tasteless gas that makes up about 78% of Earth’s atmosphere. It’s vital for life as it’s a key component of proteins, DNA, and other essential molecules. Nitrogen is commonly used in various industries, including food packaging, electronics manufacturing, and pharmaceuticals. It’s also used to preserve perishable items and create an inert atmosphere in many processes. Overall, nitrogen plays a crucial role in both natural and industrial environments.

Types of Nitrogen Generation

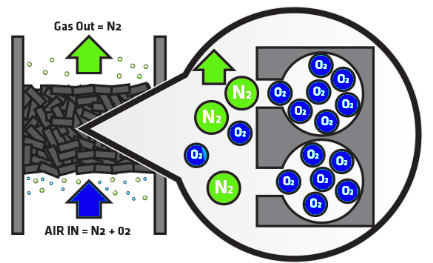

- Pressure Swing Adsorption (PSA:

PSA utilizes the principle of adsorption to separate nitrogen from other gases in the air. It involves passing compressed air through a bed of adsorbent material, typically carbon molecular sieves or zeolite, which selectively adsorb oxygen and other trace gases while allowing nitrogen to pass through. By alternating between adsorption and desorption cycles at different pressures, nitrogen is efficiently separated and collected.

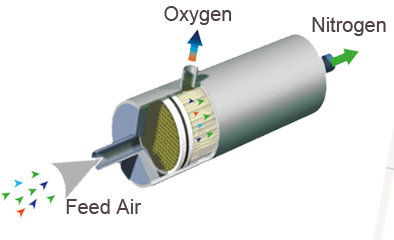

- Membrane Separation:

Membrane nitrogen generators employ semi-permeable membranes to selectively permeate nitrogen molecules over oxygen and other gases. Compressed air is passed through the membrane modules, where nitrogen molecules diffuse more readily, leaving behind oxygen and other components. This method is suitable for applications requiring moderate purity levels and lower flow rates

- Cryogenic Distillation:

Cryogenic distillation is a process that relies on the differences in boiling points of air components to separate nitrogen from other gases. Compressed air is cooled to very low temperatures to liquefy the air, and then it’s fractionally distilled to separate nitrogen from oxygen and other gases. This method is highly efficient and capable of producing high-purity nitrogen, making it suitable for critical applications such as pharmaceutical and semiconductor manufacturing

PSA Nitrogen Generation Applications and Point of Use

- Food Packaging: Modified Atmosphere Packaging (MAP): PSA-generated nitrogen helps displace oxygen in food packaging, extending the shelf life of products by slowing down oxidation and microbial growth.

- Electronics Manufacturing: Soldering and Wave Soldering: Nitrogen creates an inert atmosphere, preventing oxidation during the soldering process, leading to higher-quality electronic components.

- Pharmaceuticals: Blanketing and Inerting: Nitrogen is used to create inert environments in pharmaceutical manufacturing processes, protecting sensitive materials from exposure to oxygen and moisture

- Laser Cutting and Welding: Enhanced precision by using nitrogen as an assist gas, laser cutting and welding processes can achieve cleaner cuts and welds with reduced oxidation, enhancing the overall quality of the finished products

- Oil and Gas:Pipeline Maintenance: Nitrogen is employed for pipeline purging and blanketing to prevent the formation of explosive atmospheres during maintenance activities

- Wine Production: Nitrogen gas is an essential tool in wine production, helping winemakers preserve the quality, flavour, and stability of their wines from fermentation through bottling and storage

Advantages of PSA Nitrogen Generation:

- On-Site Generation: PSA systems allow industries to produce nitrogen on-site, eliminating the need for storage and transportation of nitrogen gas cylinders

- Cost Efficiency: Continuous nitrogen production results in cost savings compared to traditional nitrogen supply methods

- Customization: PSA systems can be tailored to meet specific purity and flow rate requirements, providing flexibility for diverse industrial applications

- Environmental Impact: On-site nitrogen generation reduces the carbon footprint associated with transporting nitrogen cylinders

PSA nitrogen generation has emerged as a reliable and cost-effective solution for meeting the growing demand for nitrogen across various industries. Its adaptability, efficiency, and on-site generation capabilities make it a preferred choice for businesses seeking enhanced control over their nitrogen supply. As technology continues to advance, PSA systems are likely to play an increasingly vital role in shaping the future of industrial gas supply.